Engineering Class Drive Chain is created for electrical power drives, construction machinery and conveyors. It operates beneath the most extreme circumstances at moderately large speeds. It truly is produced in accordance to ANSI or manufacturer’s standards. It could be interchanged with conventional chains of other companies, based upon the size. There are four fundamental types.

Style one

Normal offset design and style includes a roller, bushing, pin and conventional offset sidebars

Style two

Particular made offset sidebars have a roller, bushing, pin and  offset sidebars which have been specially formed to optimize articulation in which

offset sidebars which have been specially formed to optimize articulation in which

Design 3

Steel bushed offset sidebar chain features a bushing, pin and offset sidebars. It doesn’t possess a roller

Design 4

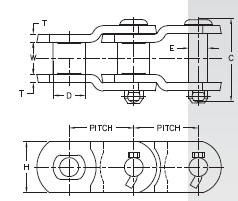

Straight sidebar drive chain features a roller, bushing, pin and straight sidebars

MXS along with other drive chain is accessible with pitch at present ranging from one.500” to 7.000”. Typical greatest strength ranges from 20,000 to 600,000 pounds and operating loads are available from 2,300 to thirty,600 pounds. Drive chains can be found in cottered building only. the pins are press fitted into the sidebars, preventing pin rotation through chain operation. This also acheives optimum bearing surface among the pin along with the sidebar. Offset drive chain must be run with the closed end to start with since the path of travel. Sprockets can be found for all applications of our chain.