Large energy roller chains with enhanced fatigue power and effect power

HI-PWR-S roller chains are enhanced in fatigue strength and influence power without the need of altering the dimension from the pin length direction of typical roller chains. Plates are enlarged, and also the machining accuracy and assembling accuracy of elements are enhanced. The roller chains hold large transmission efficiency for applications from minimal to higher  speeds and therefore are highly effective enough to stand up to long-term use.

speeds and therefore are highly effective enough to stand up to long-term use.

Recommended uses

?Compared to regular roller chains, HI-PWR-S roller chains are larger in highest kilowatt rating by about 30 percent inside a medium to lower pace array. They exhibit superb capability in destinations wherever big shock loads are applied, drive units for frequent start/stop, and in addition in substantial velocity applications.

?Civil engineering machines this kind of as skid steer, trenchers, trucks, cranes, agitating trucks, forklifts and drive units for conveyors, elevators, stackers, and so forth.

Collection of chains

Normally, pick your chain with reference to “Designing of Chain Transmission” and also on the tables of “Drive Performance” and “Dimensions” of HI-PWR-S sort roller chains.On the other hand, only for any distinctive situation of low velocity and less shock, “Low-speed selection” is also applicable.

Sprockets

HI-PWR-S Roller chains and ANSI conventional chains will be the same in essential dimensions. Use ANSI typical sprockets.

Connecting links and offset links

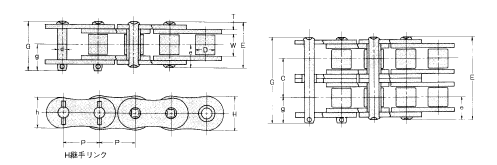

Use H connecting back links for HI-PWR-S. In an H connecting website link, the pins are lightly interference-fitted with all the connecting plate. For your connection concerning the connecting plate and also the connecting pins, spring pins are utilised in place of cotter pins to get a typical roller chain.

The center plates of an H connecting hyperlink for multiplex chain has bushings pressed in.

HI-PWR-S roller chains tend not to have any offset link. Use an even amount of back links.

Under no circumstances make the holes of the connecting plate larger and in no way make the pins thinner to facilitate the do the job for fitting the pins in to the connecting plate, given that otherwise the fatigue strength is going to be lowered.